Customer:

Meritor

eLIPS gives Meritor full control over advanced production logistics

Meritor HVS AB manufactures front and rear axles for heavy vehicles. Processing, manufacturing and assembly are conducted locally in the factory in Lindesberg, Sweden – everything from raw materials to finished axles. When Meritor needed to replace its systems for warehouse and production logistics, the choice fell to Prevas and eLIPS. This was the beginning of long and fruitful collaboration that continues to this day.

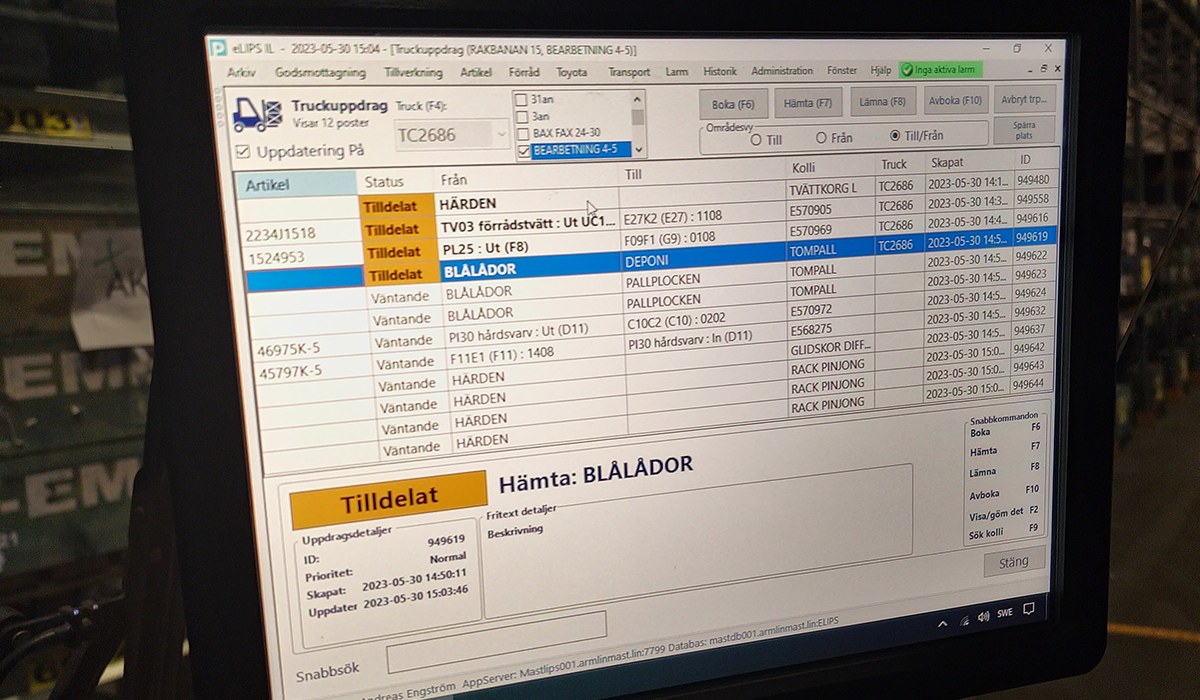

eLIPS is a technical platform, developed by Prevas, that provides full control over products in production and enables just-in-time material deliveries to all production units. eLIPS provides full support for functions such as transportation control, warehouse and inventory management, location selection, incoming and outgoing goods as well as transport order management. The background to the deployment of eLIPS at Meritor in Lindesberg was that the company had used a number of older systems that could no longer meet Meritor's production and support needs.

“As a client, it is important to first and foremost be clear about what we want to achieve,” says Stefan Svanholm, project manager at Meritor in Lindesberg. “Once this is done, we can work closely with our suppliers that can make it happen. Prevas has been both responsive and proactive, which creates the conditions for support in day-to-day operations. This enables us to thoroughly optimize our flows and production.”

Internal logistics solution 30 years old

Collaboration between Meritor and Prevas began with a feasibility study on the three existing systems for case, gear and pallet storage. Two of the warehouses are now controlled by eLIPS systems and work with the third is planned. In addition, eLIPS serves as a base for internal orders and transport assignments. With thirty years in the market, Prevas has built up a considerable bank of experience from internal logistics solutions that enable rapid implementation projects with well-proven solutions.

“The major advantage of eLIPS is its scalability and that the system is built from the ground up to adapt functions based on the needs of the organizations,” says Martin Friberg, senior software developer at Prevas and system manager for eLIPS. “The solution can also be used with existing legacy equipment and technology, making our solution cost-effective.”

The introduction of eLIPS at Meritor has been conducted in a number of independent projects starting in 2017, where eLIPS is implemented, and then continuously adapted and developed to the needs that arise in the organization. At Meritor's site in Lindesberg, the main task of eLIPS is to provide interfaces for the use of automation equipment such as cranes, AGVs, manual forklifts and track systems. In addition, eLIPS gives users full control over the location of the material at the factory. Because eLIPS integrates with production equipment with high demands on running 24/7, a system with very high availability is required; eLIPS architecture is designed to meet these requirements.

Collaboration highly valued

“With the kind of complex operations Meritor has, with high demands on availability and adaptability based on a changing business, is perfect for eLIPS,” says Martin Friberg. “Collaboration with Meritor has always been characterized by a sense of give and take, working together to make improvements and solve problems.”

With its user-friendly process support for internal logistics, eLIPS is a very central and appreciated part of Meritor's operations.

"The functionality is the most important thing, that eLIPS can be adapted to our existing equipment, the size of the factory and the needs of our users,” says Stefan Svanholm. “We were aware of eLIPS and had good experiences from previous collaborative projects with Prevas, and everything has gone well this time too.”

Keywords

Production logistics, warehouse logistics, internal logistics

Contact us

Åsa Sandberg, Prevas AB, e-mail

Related cases

-

Kenvue

Johnson & Johnson’s Consumer Business Spin-Off to Kenvue – Prevas Leads the IT Application Migration for Kenvue's Helsingborg Factory

-

Emerson

Updated I/O box future-proofs Emerson's tank radar system

-

Municipality of Karlstad

Municipality of Karlstad secures the future of water supply and wastewater maintenance with HxGN EAM

-

Göteborgs Spårvägar

Standardized and cloud-based maintenance system – collaboration between Göteborgs Spårvägar and Prevas