Customer:

Orica Mining Services

Traceability Systems to Orica Mining Services

Explosives in the wrong hands make the world ever more dangerous. The new Explosives Directive of the EU, whose implementation in Sweden is supervised by the Swedish CIVIL Contingencies Agency (MSB), along with Prevas’ traceability solutions are import ant ways forward.

Assignment: Traceability system, Manufacturing Execution Systems (MES).

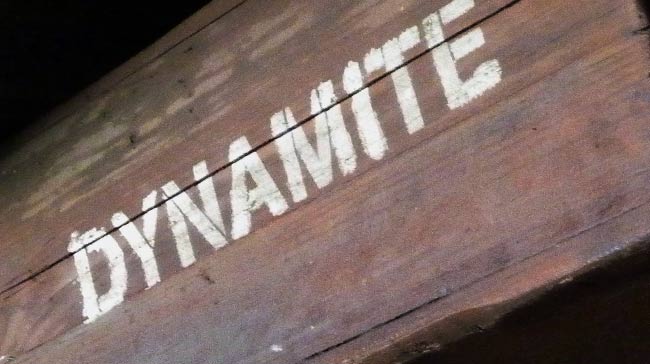

Different typesof explosives are used in terrorist attacks. Consequently, increasing safety in the handling of explosives is a prioritized issue in the European Union. It is essential that companies, making and handling explosives, have traceability systems covering such goods so that the whereabouts and the latest registered owner of them can be identified, at any time. A prerequisite for the maintenance of correct and full details of such goods, throughout the entire distribution chain, is that each item is equipped with a unique identity marking and that each link in the chain employs a system that is able to keep track of each such item. Such a system will facilitate the tracing of each such potentially dangerous item, from production to final use.

Orica at Gyttorp, Sweden, makes and handles different types of explosives for civil use, including bulk explosives, igniters and different types of cassetted explosives. The buyers are primarily civil engineering firms, mining companies and assembly facilities throughout the world.

Mats Eurén is Prevas’ liaison officer vis-à-vis Orica for its traceability system:

“Orica was very satisfied with our prestudy and chose to continue cooperating with us for implementation of a suitable system. On the basis of Prevas’ MES system platform and in close cooperation with Orica, on the basis of our prestudy, we developed a system framework focusing on consistency in presentation and functionality. All for the purpose of simplifying the tasks of users and increasing flexibility.”

Orica has managed to involve its staff during implementation very well. The process has been evaluated continually to ensure maximum acceptance from users and thereby maximum utility from the system in the years ahead.

Currently, the system, as installed at Orica, consists of everything from the marking of finished explosives cassettes (including igniters/fuses), cartons with 60 cassettes (semifinished) right up to entire pallets with 32 cartons. The markings are based on a site code and a serial number.

Do you want to know more about this project or find out what Prevas can do for you, please contact us.

CONTACT US

Peter K Johansson, e-mail

Related cases

-

#makeReference( $imgNode $customerName $title $articleLink )

#makeReference( $imgNode $customerName $title $articleLink )

#makeReference( $imgNode $customerName $title $articleLink )

#makeReference( $imgNode $customerName $title $articleLink )