Customer:

Hexagon Ragasco

Efficient stock management and reduced waste with HxGN EAM

Hexagon Ragasco, the world's leading manufacturer of composite gas containers, has achieved considerable success through efficient and automated production with minimal downtime. Prevas has assisted with implementation of warehouse management in HxGN EAM. This solution has revolutionized their inventory management and resulted in significant benefits, including reduced waste and more control in day-to-day operations.

HxGN EAM is an enterprise asset management system that helps businesses digitalize and optimize maintenance management.

“Hexagon Ragasco only produces to order and for customers all over the world, and are often faced with short deadlines,” says Atle Rørhus, who is one of those behind the company's fully automated operations. “This gives them a significant competitive advantage in the industry. Their advanced production line can produce one gas container every 10.5 seconds. Uptime at the factory is absolutely critical for our ability to deliver and consequently, the small maintenance windows we have must be fully utilized.”

Effective solutions

Before implementing the warehouse management solution, Hexagon Ragasco used manual procedures to keep track of spare parts, tools and inventory. After the introduction of the new solution, they have experienced significant improvements, with fewer misregistrations, reduced waste and a lower number of discrepancies when counting items. This has resulted in more efficient stock management, and helps to optimize the operating processes.

“In the past, we often had to implement express deliveries with all the associated costs when critical parts were not available in stock,” says Emil Nordsetmoen, system manager for HxGN EAM at Hexagon Ragasco, who has worked on development of the integration together with Prevas. “We now work much more efficiently and have full confidence that we will always have the parts we need.” For the person on the next shift who continues with a job, everything is clear and easy so that downtime is minimized.

Through implementation of HxGN EAM and integration with the warehouse automation solution, Hexagon Ragasco has achieved significant improvements. They are using the Tornado Automated Storage Tower, a vertical lifting system, for storing spare parts and tools. This has contributed to attaining more floor space, increased productivity and improved picking efficiency.

“Implementation of the EAM system and integration with the warehouse robot solution has been a tremendous success,“ Emil Nordsetmoen adds.

Caroline Hagen and Tom Thoresen (from Prevas), Atle Rørhus and Emil Nordsetmoen (from Hexagon Ragasco).

Full control and traceability

HxGN EAM has given Hexagon Ragasco the ability to follow every single step in the warehouse management process and to continuously ensure full traceability of spare parts. This has resulted in reduced waste and a significant improvement in inventory counts, with low deviations in annual counts. The risk of using the wrong parts or tools is also reduced as the system only allows the selection of parts that suit the particular pieces of equipment.

Simple and clear operation

“With HxGN EAM, Hexagon Ragasco can easily monitor lending of parts and tools, and maintain a good overview of who has borrowed what at all times,” says Emil Nordsetmoen. “If they need a specific part or tool, they can easily check the system to see where it is and if it is available. Everything is logged in the system, which makes reporting quick and easy.

”Sustainability and cost savings

Through optimized equipment maintenance, Hexagon Ragasco both saves money and safeguards the environment. By having full control over stock, they avoid ordering parts that are already in their warehouse. This contributes to sustainable production and reduces their climate footprint, while at the same time, keeping costs down.

How does integration between HxGN EAM and the warehouse robot work?

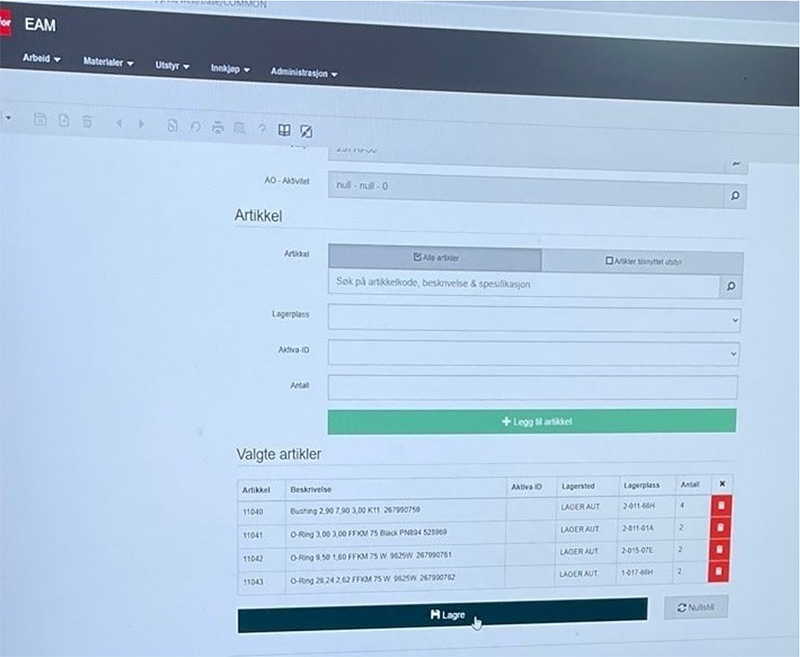

The process starts in HxGN EAM. Emil looks up the equipment on which maintenance is to be carried out. Here, both spare parts and tools needed for the job are connected.

The parts (articles) then appear in the list and Emil confirms the proposal from the system

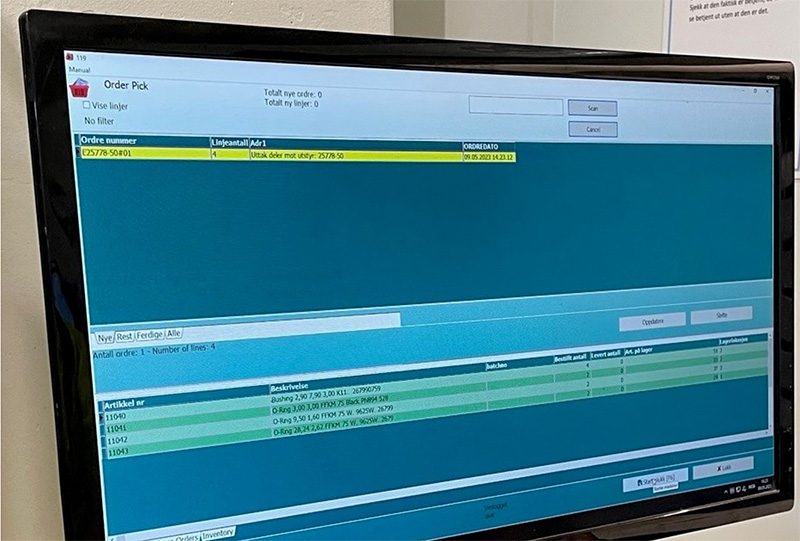

With the press of a button, the order lines are transferred to the warehouse robot and the parts are ready for automatic delivery from the goods lift.

The goods lift finds the right tray and delivers the spare parts. Now just follow the instructions and choose the right “box”.

Once you have picked the parts, stock and withdrawals are automatically registered back in HxGN EAM so that any purchases can be made in relation to, for example, minimum stock levels and planned needs.

Achieve optimal inventory management and sustainable production with Prevas

Integration of the warehouse robot and EAM solution has proven to be a powerful combination for Hexagon Ragasco. 1 + 1 has become 3. By avoiding double registration, reducing human error, eliminating costly rush orders and minimizing factory downtime, they have achieved a significant improvement in efficiency and productivity. In addition, efficient stock management has helped to reduce their climate footprint and ensure sustainable production.

In summary:

- Avoid double registration

- Reduce human errors and ensure the right parts and the right tools for the task at hand

- Avoid costly rush orders

- Minimize downtime for the factory/equipment

- Effective stock management reduces the climate footprint and ensures sustainable production

With Prevas' expertise and innovative solutions, Hexagon Ragasco has achieved optimal warehouse management, which gives them a competitive advantage and the opportunity to deliver quality products to customers on time. This is an example of how the correct implementation of technology and services can transform a company and increase efficiency at all levels.

By choosing Prevas as a partner, your business can also achieve similar benefits. Get in touch today to find out how Prevas can help you optimize your EAM solution.

Keywords

Inventory management, EAM, maintenance system, automation

Contact us

Einar Alexander Andersen, Prevas AS, e-mail

Related cases

-

Municipality of Karlstad

Municipality of Karlstad secures the future of water supply and wastewater maintenance with HxGN EAM

-

Hexagon Ragasco

Efficient stock management and reduced waste with HxGN EAM

-

Göteborgs Spårvägar

Standardized and cloud-based maintenance system – collaboration between Göteborgs Spårvägar and Prevas

-

Scatec ASA

Digitized maintenance solution for solar cell plants