Customer:

FLIR Systems

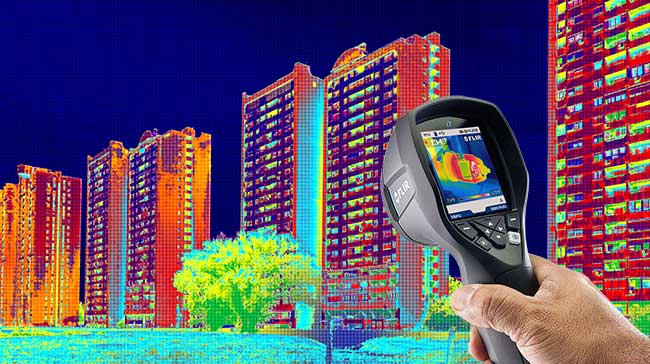

Thermal cameras – from idea to finished product

FLIR Systems’ goal is to develop thermal cameras and IR technology that improve and even save people’s lives. The products used by businesses and consumers all over the world are manufactured in Täby/Sweden.

The company produced its first thermal camera more than 40 years ago, then under the name AGA Infrared Systems. More than 400 people now work at FLIR Systems’ new facilities in Täby, outside Stockholm. All operations– development, testing, verification, production and calibration – are gathered under the same roof.

“We develop everything from simpler thermal cameras that can be used with smartphones, to advanced systems for research and development,” says Joakim Fjäder, who leads FLIR’s FPGA team. “The products are used in for example, crime prevention, energy saving, medicine and environmental protection.”

NEW APPLICATION AREAS

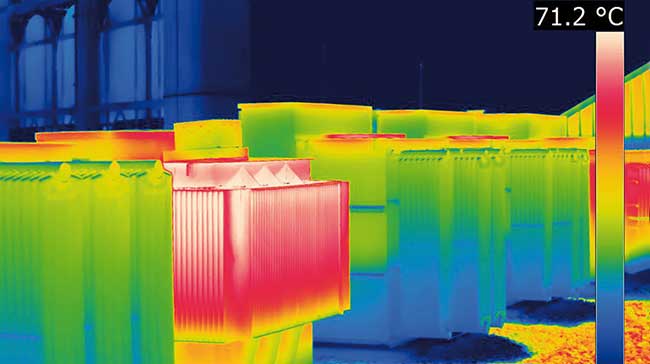

General technical development and digitalization in industry and society are creating new application areas for FLIR's products. An example is drones equipped with thermal cameras to monitor crops, inspect solar panels and obtain information on the spread of fires. In industry, thermal cameras are used in quality control and monitoring to avoid downtime, for example.

As the prices of thermal cameras fall, the technology is becoming more accessible for both businesses and consumers. At the same time, customers expect the same performance and graphics experiences as they have in their smartphones, which puts pressure on product development.

“I’m proud that we've succeeded in achieving such a high level of imaging,” says Joakim. “There are relatively few of us developers behind these advanced products, but it works thanks to our experience and passion for what we do.”

BASED ON FPGA TECHNOLOGY

FLIR uses FPGA circuits in their cameras and this is also what Joakim and his development team work with. An FPGA – field-programmable gate array – is a digital, integrated circuit that is programmed after manufacture to handle a specific function. The same circuit can be used for different tasks depending on how it is coded. In an FPGA circuit, all blocks can be run in parallel and its architecture provides high calculation capacity in relation to power consumption. In FLIR's case, energy consumption and high data rates are important parameters.

“Because our cameras measure and visualize heat, we have to minimize self-heating,” Joakim explains. “At the same time, it's essential to achieve high calculation speed as well as good battery life for systems that are handheld. FPGA programming is like putting together a complicated puzzle and it requires experience and thorough understanding of how the code is translated to FPGA primitives.”

PREVAS STRENGTHS THE TEAM

The FPGA team consists of ten developers – seven are employed at FLIR, one is a consultant working on-site at FLIR and two are working in Poland at the site of a collaborative partner. Prevas consultant Johan Degerman has been on the team since 2015.

“FLIR's thermal cameras incorporate incredibly exciting technology and FPGA plays a key role in the products,” says Johan. “Because product development and production are at the same location, we get immediate feedback on what we've done and we can make quick decisions. This makes the job interesting, dynamic and also lots of fun.”

Johan, who has a degree in computer science from Umeå University, has worked at several consulting firms and been involved in development projects for many different customers. He enjoys working at FLIR, and not just because of the interesting technology the company develops.

“The working environment is relaxed and it’s easy to reach agreement with my colleagues,” says Johan. “Despite the high level of expertise, the company culture is free from prestige conflicts and you always feel like you can ask questions and speak your mind. I also feel that people want to hear my ideas and opinions, which isn't always the case as a consultant.”

The members of the FPGA team have broad collective expertise, encompassing among other things imaging, memory management and electrical interfaces. FLIR has worked with Prevas for several years to complement its own expertise.

“When we've needed external resources, Prevas has always been able to provide truly good candidates. Senior experts with the right experience and skills,” says Joakim. “Many fulfill the same formal requirements, but the ability to quickly come up to speed in our operations has been decisive for us.”

“We develop market-leading products in a technical area where we are constantly discovering new opportunities. It feels especially good that we do everything here in Sweden, from preliminary studies to production. I can follow development from an idea to a finished product that I can hold in my hand,” says Joakim in closing.

Do you want to know more about this project or find out what Prevas can do for you, please contact us.

CONTACT US

Per Eriksson, Sales Manager, e-mail